This interview of CEO & Founder, Kahlilah Guyah, was originally featured in the EHS Daily Advisor’s Faces of EHS. It’s a new year, and we’re…

While presenting at the Cal/OSHA Safety Summit this week, I challenged attendees to write down one key takeaway, priority or action step from the presentations…

When I was employed by Johnson and Johnson over a decade ago, sustainability became one of the focus areas; but, at that time, sustainability was…

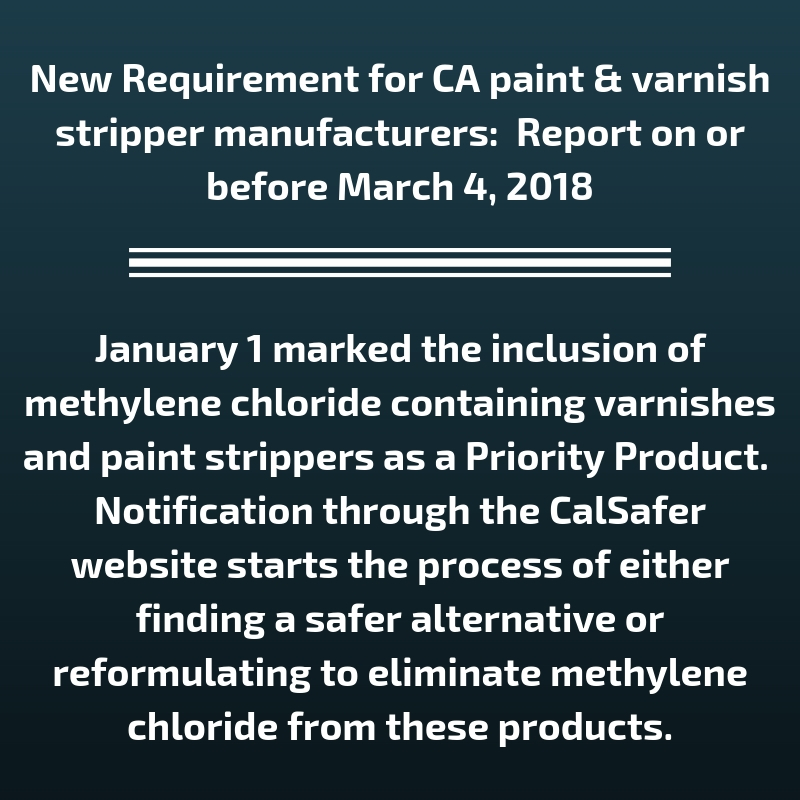

Changes to the California Department of Toxic Substances Control’s (DTSC) Safer Consumer Products program adds methylene chloride containing varnishes and paint strippers to reporting requirements.…

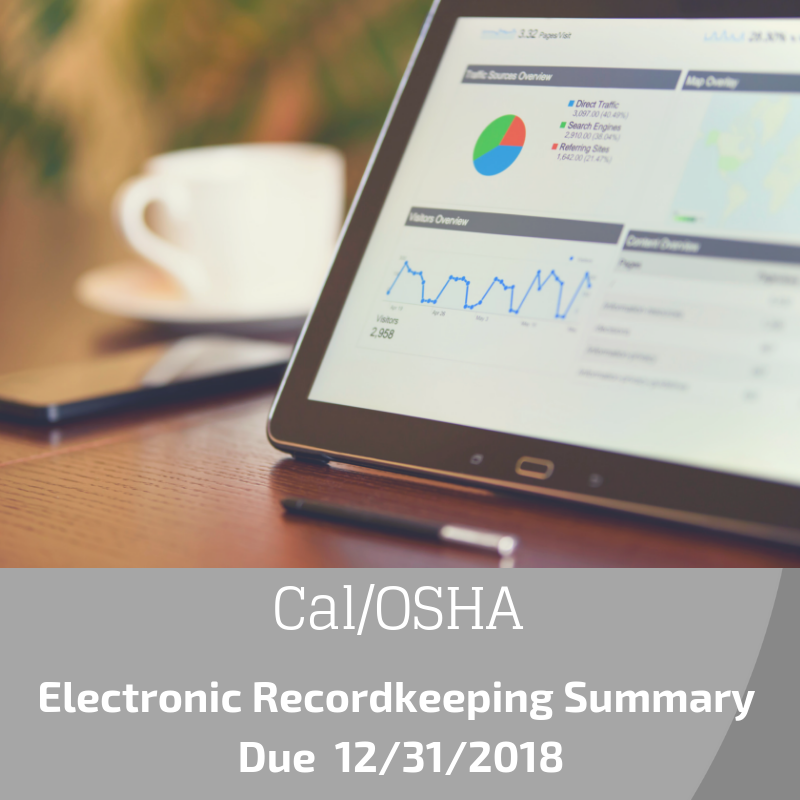

The Cal/OSHA electronic report of injuries and illnesses is due December 31, 2018, for establishments with 250 or more employees (if not specifically exempt) and…

A newly released study links exposure to fine particles found in vehicle exhausts, industrial emissions and other sources of outdoor pollution to increased risk of…

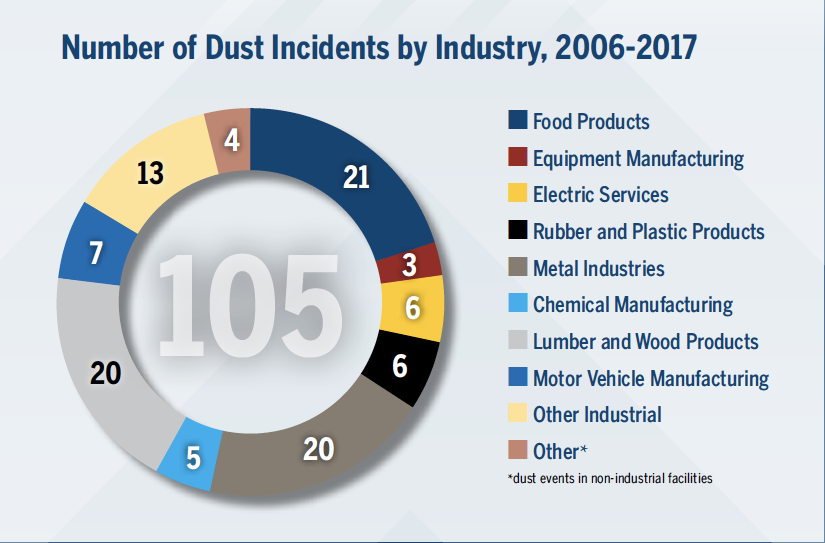

Combustible dusts are in the spotlight again! The CSB recently reported 105 combustible dust incidents between 2006 and 2017. Having clients in a number of…

The Environmental Protection Agency (EPA) will begin implementation and operation of the e-Manifest system on June 30, 2018. The e-Manifest requirements will be effective in…

On November 28, 2016, the Environmental Protection Agency (EPA) issued a final rule that significantly revises hazardous waste generator regulations. These revisions provide less stringent…

By Guest Blogger: Lisa Stringfellow of Graphic Products On December 1, 2013—about one year from now—the implementation of training to the new Hazard Communication Standard (29…